Engineering

INNOVATIVE AVIATION SOLUTIONS FROM ONE SOURCE

Transform your ideas into reality with our cutting-edge design solutions. At EME, we blend innovation with precision to create technical designs that drive success. Let us help you bring your projects to life with expertise and creativity! Our skilled in-house engineering team is fully equipped to manage and support the entire product lifecycle – from research and development to design, prototyping, qualification, and ongoing product support. With expertise in both mechanical and electrical/electronic components, EME specializes in the complete development of a diverse array of aviation systems, along with all the necessary regulatory documentation.

Design

Achieving superior aircraft components

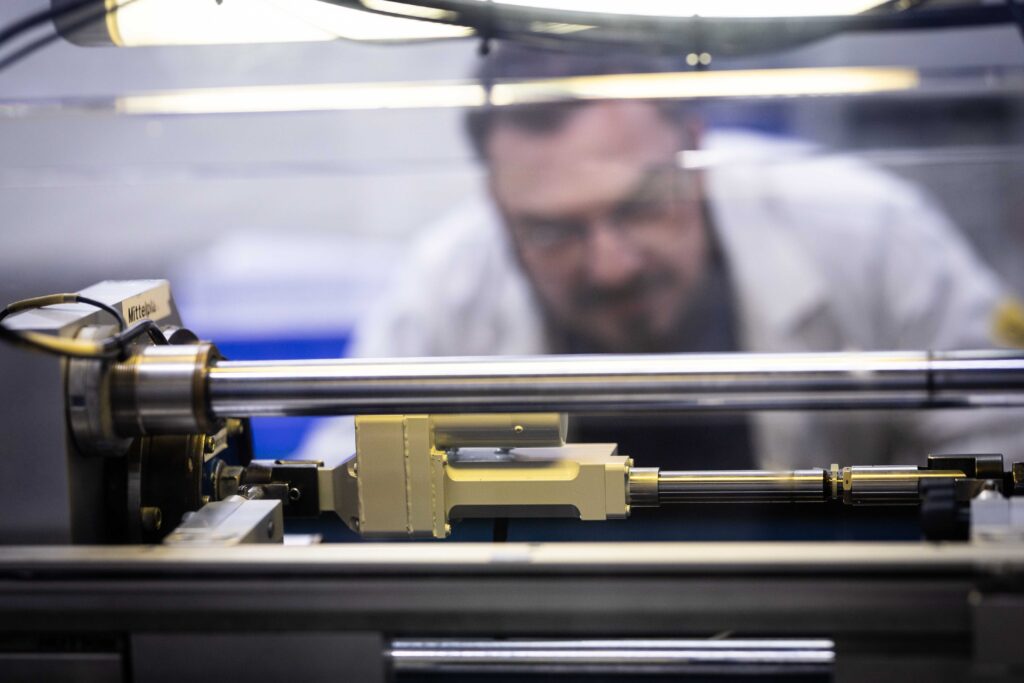

Prototyping

Driven by innovative processes

Although most specification requirements and characteristics can be validated to a fair degree by means of computer-aided simulation and modeling today, prototyping is still an indispensable step in the development process of aircraft components.

EME’s prototyping specialists utilize rapid prototyping techniques, such as additive layer manufacturing, to swiftly create scale models of physical parts or assemblies for testing and engineering evaluations. Additionally, a range of high-performance CNC machines is available to quickly produce a wide variety of parts.

Testing

for the highest product quality

We conduct a comprehensive range of engineering tests throughout the entire product development cycle. Each development phase is paired with testing to secure design confirmation as early as possible, while also enabling further optimization in time for the next Design Review. Production testing is the key to deliver reliable and dependable products to our customers. Our engineering team develops Acceptance Test Procedures tailored to the unique characteristics of each product, ensuring the highest standards of quality.

Qualification

Ensuring performance, reliability, and full compliance

EME is a leader in the development and manufacturing of advanced electro-mechanical components for specialized applications. We deliver products with the highest levels of maturity and reliability, trusted worldwide. Each of our high-quality products undergoes a rigorous qualification process to ensure optimal performance.

To ensure our products not only meet but exceed technical requirements for extreme robustness, we utilize accelerated testing methods like HALT (Highly Accelerated Life Testing). Our extensive experience includes:

- FAA/EASA Qualification

- RTCA DO-160

- RTCA DO-254

- MIL-STD 461/810″

Technical Documentation

Securing full approvals

Legal, contractual, and industry standards require detailed technical documentation. EME supports all documentation needs, from component and assembly approvals to project qualification and certification. Our services include, but are not limited to:

- Comprehensive documentation according to customer-specific Quality Systems

- Written evidence and calculations covering performance, static strength, fatigue, thermal loads, safety, and reliability

- Documentation from qualification testing for various environmental conditions and endurance

- IP data and data modules (ATA iSpec 2200, ASD S1000D) for product support